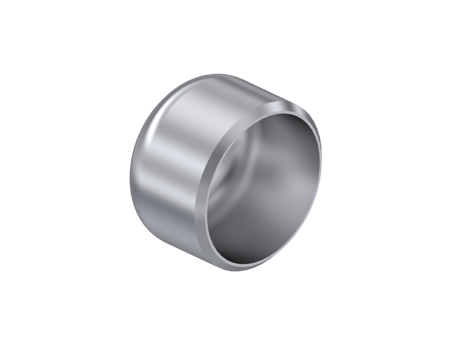

Pipe end caps

Enhancing Fluid System Integrity with Aseptconn’s Pipe End Caps

In industries where cleanliness and system integrity are paramount, such as pharmaceuticals, biotechnology, food and drink, and chemicals, the role of pipe end caps becomes crucial. Aseptconn offers a premier solution within this category to protect and seal the ends of tubes, ensuring system reliability and hygiene. Among their offerings, the tube weld cap according to ASME BPE - 316L / DT-4.1.5-1 stands out for its exceptional quality and compliance, demonstrating Aseptconn's commitment to meeting the industry's stringent standards.

Understanding the Importance of Pipe End Caps

Pipe end caps play a vital role in maintaining the sterility, purity, and integrity of fluid handling systems. By securely sealing tube ends, they prevent contamination, protect against environmental factors, and ensure that the systems remain closed and safe. Suitable for a wide range of applications, from pharmaceutical production lines to chemical processing plants, Aseptconn’s pipe end caps are designed to meet diverse operational needs.

Key Features of Aseptconn’s Tube Weld Cap According to ASME BPE - 316L / DT-4.1.5-1

Material Excellence

Crafted from 316L stainless steel, the tube weld cap according to ASME BPE - 316L / DT-4.1.5-1 is celebrated for its superior corrosion resistance, durability, and compatibility with strict hygiene requirements. This material ensures that the cap can withstand the demanding conditions of sensitive environments without compromising system integrity. Additionally, for bespoke requirements, the option for material 1.4435 BN2 is available upon request, offering tailored solutions to meet specific operational needs.

Optimal Surface Quality

The tube weld cap offers two finishes to cater to different industry standards and cleaning requirements:

- Electropolished (SF4): Achieving an internal surface roughness of ≤ 0.38 µm, this finish guarantees an ultra-clean surface, crucial for minimizing contamination risks and ensuring easy maintenance.

- Bright Finished (SF1): With an internal surface roughness of ≤ 0.51 µm, it provides a high-quality yet cost-effective solution, maintaining essential cleanliness without sacrificing performance.

These finishes are complemented by an outer surface Ra value of ≤ 1,00 μm, ensuring the cap’s quality is as robust on the outside as it is on the inside.

Tailored Applications

Designed with the rigorous environments of the pharma & biotech, food and drink, and chemical industries in mind, the tube weld cap is a critical component for systems demanding the highest levels of sterility and integrity. Its conformity to ASME BPE standards highlights its suitability for applications where precision and reliability are non-negotiable.

Customization and Compliance

The tube weld cap not only adheres to the prestigious ASME BPE standards but also comes with an acceptance test certificate according to EN 10204-3.1. This certification underscores its quality and compliance, providing peace of mind to industry professionals. Furthermore, Aseptconn accommodates the need for custom dimensions and materials, ensuring that every system’s unique requirements are met with precision.

Conclusion: A Comprehensive Solution for Fluid System Protection

Aseptconn’s Tube weld cap according to ASME BPE - 316L / DT-4.1.5-1 represents an essential component for ensuring the integrity and cleanliness of fluid handling systems in critical industries. By offering a product that combines exceptional material quality, superior surface finishes, and adherence to stringent industry standards, Aseptconn enables enhanced system protection and operational excellence. This weld cap not only meets the demanding requirements of today’s industries but exceeds them, reinforcing Aseptconn’s role as a leader in the field of precision-engineered fluid handling components.

Want to Learn More?

For product inquiries or other concerns, we are happy to assist you. Simply share your concern via our contact form, and we will get back to you promptly.

Interested in exploring Aseptconn's complete selection of tubes and wield fittings? Dive into our comprehensive range, featuring everything from standard tubes, 45° elbow tubes, 88° elbow tubes, 90° elbow tubes, and 92° elbow tubes to pipe end caps, along with T-pieces, reduced T-pieces, and concentric reducers or eccentric reducers.

Looking for additional products tailored to your industry needs, such as quick couplings, pumps, hoses, and filling needles? Check out Aseptconn’s full product portfolio for all your requirements.