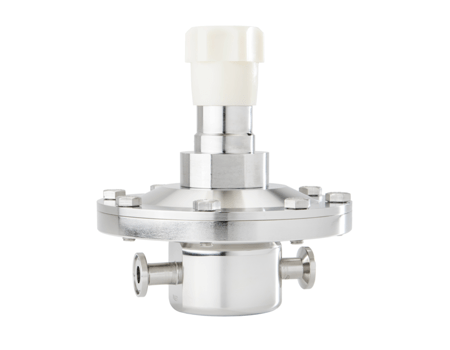

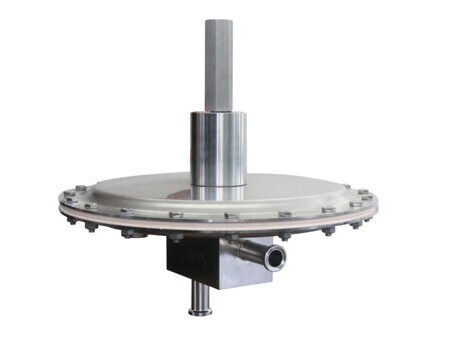

Pressure Reducing Valves Pharma and Biotek

Pressure reducing valves: a key component in the pharmaceutical and biotech industries

In the pharmaceutical and biotech industries, precision, reliability and safety play a crucial role. A critical component that meets these requirements and is essential in many applications is pressure reducing valves. These valves, also known as control valves or pressure reducers, are an important factor in controlling fluid pressure in various processes.

But how exactly do these valves work? What are they used for in the pharmaceutical and biotech sector and what do you have to look for when buying? We explain.

What are pressure reducing valves and how do they work?

Pressure reducing valves are valves that control the pressure of liquids or gases in a system. They ensure that the pressure remains constant and does not reach peak values that could lead to damage to the equipment or deteriorating product quality.

The operation of a pressure reducing valve is based on a simple principle: the valve has an adjustable spring that regulates the pressure in the system. When the pressure reaches a certain threshold, the valve opens and allows the liquid or gas to escape until the pressure is reduced to the desired level. As soon as the desired pressure is reached, the valve closes automatically and keeps the pressure constant.

Use of pressure reducing valves in the pharmaceutical and biotech industries

In the pharmaceutical and biotech industries, precise control of fluid pressure is crucial to ensure the quality and safety of manufactured products. Pressure reducing valves are used in a wide range of applications, including:

- Fermentation processes: Fermentation processes are used in the production of biotechnological products such as antibodies or vaccines. It is important to precisely control the pressure in the fermenters in order to create optimal conditions for the growth of the microorganisms.

- Sterilization: The sterilization of equipment, containers and media is an essential step in pharmaceutical and biotech production. Pressure reducing valves allow precise pressure control during the sterilization process to ensure sterilization effectiveness.

- Filling and packaging equipment: In automated filling and packaging equipment, precise pressure control is required to ensure uniformfilling of bottles or containers. Pressure reducing valves ensure constant pressure during the filling process to minimize product loss and quality issues.

Quality and reliability are crucial: The advantages of Aseptconn pressure reducing valves

For the pharmaceutical and biotech industries, the quality and reliability of pressure reducing valves are of paramount importance. They must comply with the strict requirements and regulations that apply in these industries. Aseptconn offers a wide range of the highest quality pressure reducing valves to meet these demanding requirements. In the following, we will briefly introduce you to the most important advantages of our products.

- Precise pressure control: Aseptconn pressure reducing valves are characterized by their high precision. They ensure accurate and constant pressure control, which is crucial for the quality and efficiency of production processes.

- Reliability and safety: Aseptconn attaches great importance to the reliability and safety of its products. The pressure reducing valves are made of high-quality materials and are subject to strict quality controls to ensure reliable and safe operation.

- Adaptability: Aseptconn offers a variety of pressure reducing valves that can be customized to meet customers' specific requirements. The valves are available in different sizes, pressure ranges and materials to meet the different needs of the pharmaceutical and biotech industries.

- Hygienic design: Hygiene plays a crucial role in the pharmaceutical and biotech industries. Aseptconn pressure reducing valves are designed to the highest hygienic standards. They feature smooth surfaces, rounded edges, and are easy to clean for optimal cleaning and sterilization.

Want to learn more?

We will be happy to help you with product inquiries or other concerns. Simply let us know your request via our contact form and we will get back to you as soon as possible.

Would you like to learn more about Aseptconn's product portfolio? Find the right products for pharmaceuticals, biotech, cosmetics and more in our product overview and find spare parts for plants and machines, tri-clamp connections, hoses and much more.