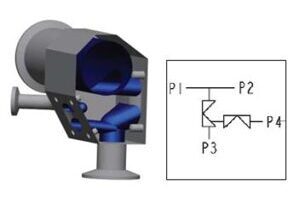

Product description

The ZDP process manufacturing is a modification of the normal zero static valve. An integral valve at the rear of the valve allows access to a Downstream of the zero static ZSBB barrier. This connection can be used for various process and supply applications, such as steam, CIP solution or gas flushing. The downstream integral purge valve typically uses 0.5" Pure-Flo valve variants. The integral purge valve significantly reduces contact areas, storage volume, and potential dead legs compared to purge valves that are externally welded to a standard zerostatic valve. The ZDP is a basic component of a piping system required to meet the demanding L/D ratios proposed in the ASME BPE standard.

Zerostatic downstream purge

- wrought

- 316L ASTM - A479

-

DIN 177440, 1.4435

-

AL6XN

-

Hasteloy C-22 & C-276

* Other Materials upon request

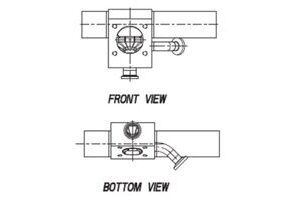

0.5" - 4" (DN 15 - 100) Main line

0.25" - 2" (DN 8 - 50) Valve line

0.5" Pure-Flo purge as standard

* Other sizes upon request

Standard

- Buttweld ends ISO / DIN / ASME

- Tri-Clamp ISO / DIN / ASME

Special endconnection upon request

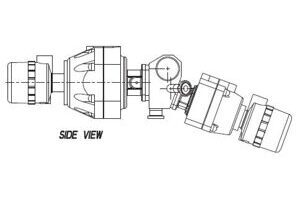

- manual

- pneumatic