Product description

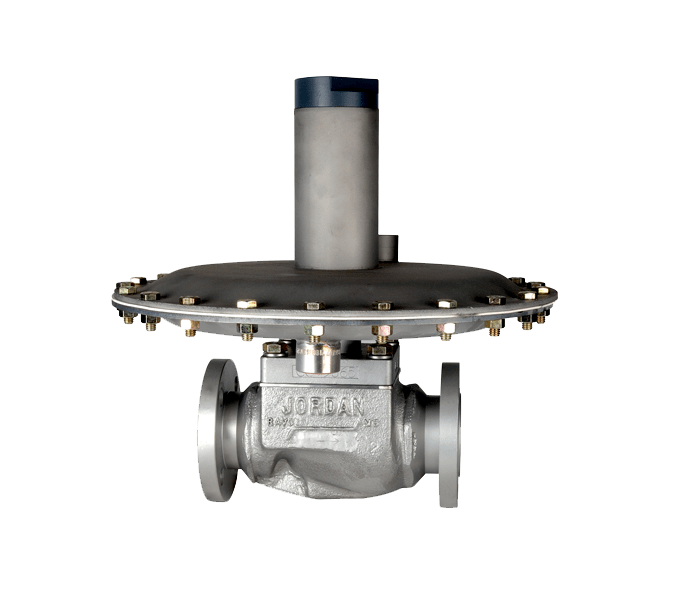

Back Pressure Reducing Valve MK508

Size

- 3/4" (DN20), 1" (DN25), 1-1/4" (DN32)

End Connections

- Threaded – NPT, SWE, BSPT, BSPP

- Flanged – 150#, 300#, PN16, PN40

Materials

- Body & Housing: Carbon Steel (A216, WCB), Stainless Steel (A351/CF8M)

- Seat: Stainless Steel

- Plug: Stainless Steel and Viton

- Diaphragm: Viton

- Aspirator Tube: Delrin/optional PTFE

- Actuator Cases: matches body material

- Actuator Diaphragm: Viton for CS and SS bodies

Temperature Range

- -20°F (-29°C) to 200°F (93°C)

Maximum Inlet Pressure

- 150 psi (10 bar)

Ranges

• 2.0 to 6 inches w.c. (5,0 to 15,0 mbar)

• 3.0 to 11 inches w.c. (7,5 to 27,4 mbar)

• 5.0 to 35 inches w.c. (12,4 to 87 mbar)

Shutoff

- ANSI Class VI

Service

- air or gas

Features and Benefits

- Body rating up to 150 psi (10.3 bar)

- Rugged, heavy-duty design – Emergency outlet pressure may reach 100% of inlet pressure without damaging valve

- 360° body orientation – Valve can be installed in any position and easily repositioned while in-line (3/4” – 1-1/4”)

- Easy maintenance – Seat and plug can be inspected without removing body from the line (3/4” – 1-1/4”)

- Completely self-operated – No external power source required

- Tight shutoff – Soft elastomer plug provides ANSI Class VI shutoff

-