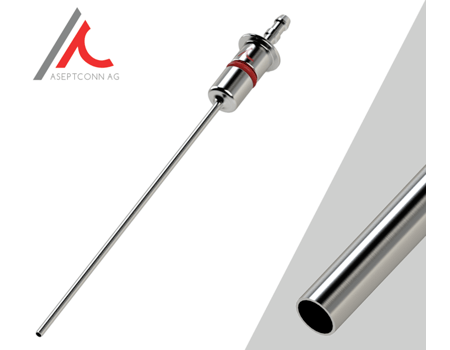

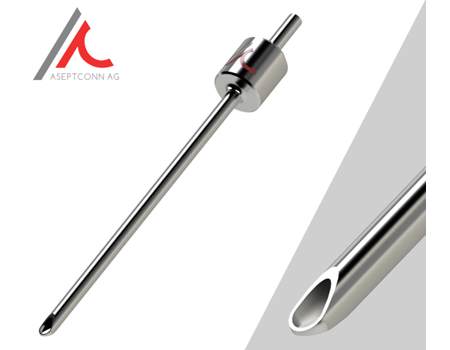

Filling Needles

FILLING NEEDLES FOR PHARMACEUTICAL STERILE ASEPTIC MACHINES

Filling Needles: An Essential Instrument in Precise Industrial Processes

In specialized fields such as biotechnology, pharmaceuticals, cosmetics, chemicals, and food production, the reliability of every individual process step is paramount. Within this framework, filling needles play a pivotal role. Their precise design and execution ensure consistent filling while simultaneously safeguarding the quality and integrity of the end product.

This section sheds light on the technical specifications and requirements of filling needles, emphasizes their central role in highly specialized industrial processes, and provides a guide on what to consider when acquiring these critical instruments.

Definition and Application Areas of Filling Needles in the Industry

Filling needles are specially designed instruments used in various industries to precisely dose liquids or semi-liquid products and fill them into containers, ampoules, or other packaging. These needles are more than simple channels; they often result from advanced engineering and material science to meet the specific requirements and standards of each industry. Here are some of the key application areas:

Biotech and Pharma: In biotechnology and pharmaceuticals, filling needles are of vital importance. They ensure accurate dosing of medications and vaccines, which is essential for both product effectiveness and patient safety. Slight deviations from the prescribed dose can impact the therapeutic effect of a medication or cause unwanted side effects.

Cosmetics: In the cosmetics industry, filling needles are used to transfer products such as creams, serums, or lotions into their final packaging. Precision is crucial here to ensure that each product contains the exact advertised amount.

Chemicals: The chemical industry also demands highly precise filling needles, especially when dealing with hazardous or reactive chemicals. Accurate dosing can help reduce waste and ensure the safe and efficient production of end products.

Food and Beverage Industry: Filling needles are also crucial in the food industry, whether it's filling sauces, dressings, or other liquid foods. The right dosing not only ensures product standards but also consumer satisfaction.

In summary, filling needles, despite their apparent simplicity, are an integral part of many industrial processes. Their ability to dose liquids with high accuracy and consistency makes them an indispensable tool in a variety of industries.

Features of a High-Quality Filling Needle and Selection Criteria when Purchasing

At first glance, a filling needle may appear to be a simple tool, but there are critical details in its design and manufacturing that determine its efficiency and reliability. By examining the following features, you can identify the right filling needle for your production:

Single-Use or Multi-Use Filling Needle: First, it is important to decide whether you need a single-use or multi-use filling needle. Both have different characteristics that you can leverage to your advantage.

Multi-Use: Multi-use needles need to be cleaned before use. However, since they can be reused several times before replacement, they offer short-term cost savings. Stainless steel needles provide a wide range of filling options that can eliminate issues like foaming or unwanted splatters. They can also be tailored to specific needs.

Single-Use: These needles do not require cleaning before use, which extends manufacturing time and reduces processing and cleaning times. Furthermore, they are self-cleaning, gamma-irradiated, and delivered in double packaging to ensure sterility. Single-use needles eliminate the risk of cross-contamination with other components since they are used only once.

Material Quality: The material from which the filling needle is made plays a crucial role. For example, stainless steel is often the preferred choice in the pharmaceutical and food industries due to its durability, corrosion resistance, and sterility.

Precision: A filling needle must be able to dose liquids in precisely defined quantities. The design of the tip and the diameter of the needle determine how accurately and uniformly the liquid is dispensed.

Compatibility: The filling needle should be compatible with the machines and filling systems used in the respective industry. Good adaptability ensures seamless integration into existing production lines.

Ease of Cleaning: An easily cleanable filling needle minimizes the risk of contamination and ensures high product quality. In industries such as pharmaceuticals or food production, this can be crucial.

Robustness: The filling needle should be resistant to mechanical stresses, high temperatures, and chemical influences. This ensures a long service life and prevents frequent failures or replacements.

Certifications: Especially in regulated industries, filling needles should comply with relevant standards and certifications. Such certificates guarantee that the product has undergone strict quality and safety checks and ensures operational safety.

When acquiring a filling needle, it is essential to consider not only the price but, more importantly, the criteria mentioned above. Careful selection guarantees not only efficient production but also the safety and quality of the end product.

Our filling needles are ideal for these filling machine brands:

- Bausch Stroebel

- Bausch Advanced Technology

- BOC Edwards - Calumatic

- Bosch - Syntegon - Strunck

- Chase-Logeman

- Comas

- Cozzoli

- Dara Pharma

- Watson Marlow Flexicon

- Groninger

- I-Dositecno - ATS

- Ima - Farmomac

- Inova

- Mar

- Marchesini – Corima

- M&O Perry

- Neoceram

- NKP Pharma

- Sfm-Steriline

- Rota

- National Instrument - Filamatic

- Optima - Kugler

- Romaco

- Pkb

- Truking

- Tofflon

- Snowbell

- Zellwag - Rychiger

Want to Learn More?

For product inquiries or other concerns, we are happy to assist you. Simply share your question via our contact form, and we will get back to you promptly.

Would you like to learn more about Aseptconn’s complete product portfolio? Find the right products for pharmaceuticals, biotech, cosmetics, and more in our product portfolio, and find kits for Skids and machines, Tri-Clamp connections, hoses and much more.