Pressure gauge

Pressure gauges – The essential measuring instruments for precise pressure measurements

Measuring is

essential in the industry. Only through accurate measurements can processes be

optimized and safety-relevant processes controlled. An important measuring

instrument is the pressure gauge, which measures the pressure of a liquid or gas

and can thus provide important information about the condition of a plant.

Get an overview

of our range of pressure gauges and improve your production processes with Aseptconn.

What is a pressure gauge?

A pressure gauge

is a measuring instrument that measures the pressure of a liquid or

gas and is usually expressed in the unit bar or pascal. It consists of a scale

on which the measured pressure can be read, as well as a measuring device that

converts the pressure into a mechanical movement and transfers it to the scale.

There are several types of pressure gauges that differ in their mode of

operation and scope of application.

How does a pressure gauge work?

A pressure gauge

is a measuring instrument that measures the pressure in a system. It consists

of a cavity filled with either a liquid or a gas. When pressure is applied to

the cavity, the volume of the medium changes. This leads to a movement of the pressure

gauge pointer. The deflection of the pointer corresponds to the measured

pressure. The higher the pressure in the system, the more the medium is

compressed and the farther the pointer of the pressure gauge moves.

What are the advantages of

pressure gauges?

We have

summarized the most important advantages of pressure gauges for you:

- Accuracy: Pressure gauges measure the pressure in a

system very accurately, which helps to ensure the production of

high-quality and defect-free end products. - Monitoring: By continuously monitoring the pressure in

a system, a pressure gauge can prevent overloads and thus contribute to a

longer service life of machines and equipment. - Fault detection: A pressure gauge helps detect leaks

or blocked pipes, which can lead to faster

troubleshooting, thus reducing downtime. - Efficiency: Accuracy and monitoring also contribute to

the efficiency of production processes by ensuring that systems are

functioning optimally. - Easy to install and operate: Pressure gauges are typically easy

to install and use, providing a cost-effective solution to measure

pressure in a system. - Versatility: Pressure gauges are available in many

different sizes and configurations, allowing them to be used for a wide

range of applications in different industries.

In which industries can

Aseptconn pressure gauges be used?

Pressure gauges

are indispensable measuring instruments in many industries to carry out precise

pressure measurements and thus optimize processes and control safety-relevant

procedures. Pressure gauges are particularly important in the biotech,

chemical, pharmaceutical, cosmetics, and food industries, as these industries

place special demands on the production processes and the quality of the end

products.

What pressure gauges does

Aseptconn offer?

In the Aseptconn

range you will find four different pressure gauges:

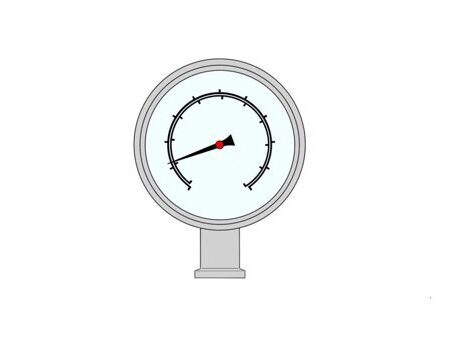

-

Pressure gauge with TC 25mm connection below

-

Pressure gauge with TC 50.5mm connection below

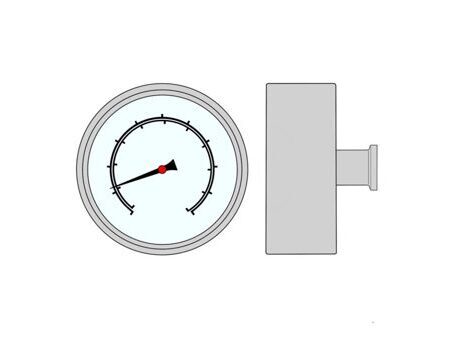

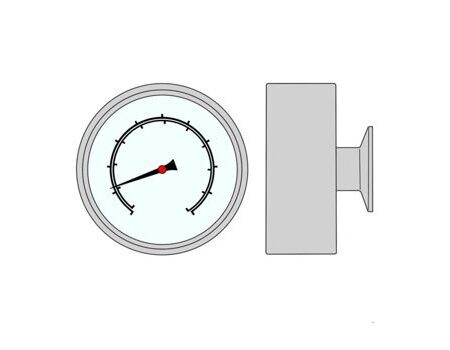

-

Pressure gauge with TC 25mm rear

connection

-

Pressure gauge with TC 50.5mm rear

connection

Want to learn more about pressure

gauges?

We are

happy to assist you with product inquiries or any other concerns. Simply let us

know your inquiry via our contact form, and we will get back to you

promptly.

Would you

like to learn more about Aseptconn's product portfolio? Find the right products

for pharmaceuticals, biotech, cosmetics, and more in our product overview. Discover products such as valves, Tri-Clamp connections, maintenance kits for equipment and machinery, and

much more.