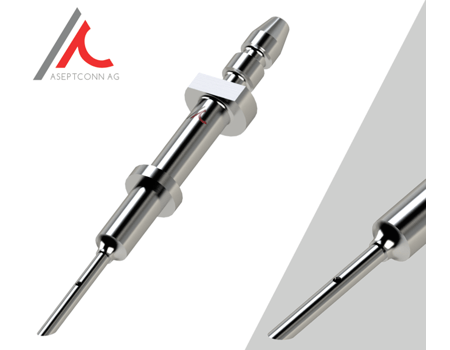

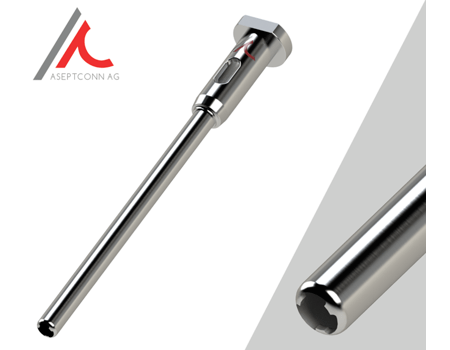

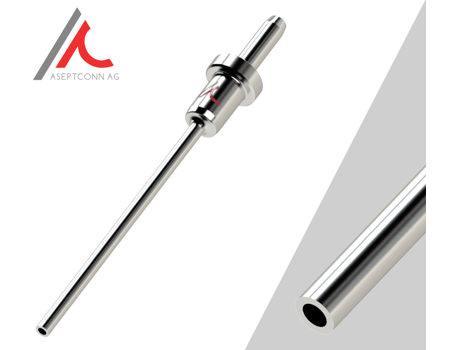

Gassing Needles

GASSING NEEDLES FOR PHARMACEUTICAL STERILE ASEPTIC MACHINES

High-Quality Gassing Needles: Efficiency and Precision in Pharma and Biotech Processes

The world of pharmacy and biotechnology demands precision, reliability, and safety at every stage of production. A crucial component that plays a decisive role in this context is gassing needles. These small yet significant tools ensure the even distribution of gases and sterile fluids in a process that requires the highest standards of hygiene and quality. We will explain how gassing needles are used in the industry, what distinguishes high-quality needles, and what criteria you should consider when making a purchase.

Definition and Industrial Applications of Gassing Needles

Gassing needles are specialized instruments used in a variety of industrial applications. Their primary purpose is to introduce gases or sterile fluids uniformly into a process to ensure sterility and control. The key application areas include:

Pharmaceutical Production: In the manufacturing of medicines and vaccines, gassing needles are essential to ensure reliable sterilization and homogenization of liquids.

Food and Beverage Industry: The production of food often requires the control of gases such as nitrogen to ensure product quality and durability.

The significance of gassing needles in these industries cannot be overstated, as they form the foundation for hygienic and efficient processes.

Characteristics of High-Quality Gassing Needles

When selecting gassing needles, there are specific features to keep in mind that distinguish high-quality needles from others. The key criteria include:

Material Quality: High-quality gassing needles are made of corrosion-resistant materials such as stainless steel or PEEK (Polyetheretherketone). This ensures long-lasting durability and sterility.

Precise Design: The needle should be designed to ensure the uniform distribution of gas or fluid, preventing hotspots.

Compatibility: Ensure that the needle is compatible with your specific application and existing equipment.

Certifications: Check if the gassing needles comply with international standards and certifications for sterilization and quality.

Consultation and Support: A reliable manufacturer provides expert guidance and customer support to ensure you make the right choice.

At Aseptconn, we offer gassing needles that meet all of these criteria and are available in various sizes and configurations. Our experts are available to assist you in selecting the appropriate needles for your specific application.

Ideal for These Filling Machine Brands

To make your choice even easier, here are all the brands for which our gassing needles can be used. Our products are ideal for these filling machines, ensuring smooth operations in all your processes:

- Bausch Stroebel

- Bausch Advanced Technology

- BOC Edwards - Calumatic

- Bosch - Syntegon - Strunck

- Chase-Logeman

- Comas

- Cozzoli

- Dara Pharma

- Watson Marlow Flexicon

- Groninger

- I-Dositecno - ATS

- Ima - Farmomac

- Inova

- Mar

- Marchesini – Corima

- M&O Perry

- Neoceram

- NKP Pharma

- Sfm-Steriline

- Rota

- National Instrument - Filamatic

- Optima - Kugler

- Romaco

- Pkb

- Truking

- Tofflon

- Snowbell

- Zellwag - Rychiger

Want to Learn More?

Choosing the right gassing needles is crucial for the success of your pharmaceutical, biotechnological, or other critical processes. Aseptconn is your preferred partner for high-quality gassing needles and other components that contribute to improving your processes. Our products are the result of innovation, quality, and years of industry experience.

If you have product inquiries or other concerns, we are here to assist you. Simply let us know your inquiries through our contact form, and we will get back to you promptly.

Would you like to learn more about Aseptconn's product portfolio? Find the right products for pharmaceuticals, biotech, and more in our product overview, including spare parts for equipment and machinery, Tri-Clamp connections, hoses, filling needles, and much more.