Product description

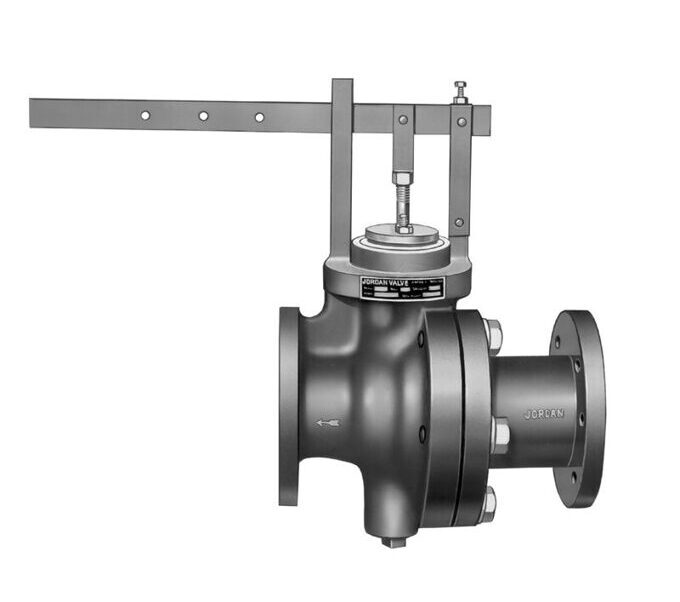

The Mark 40 and Mark 46 are designed with the unique sliding gate seats for lever control of tanks. Both valves utilize the same design with the exception of the actuator. The Mark 40 is supplied with a float actuator while the Mark 46 is supplied with a lever and a series of drilled holes for attachment to a customer-supplied actuator.

Regelventil MK40/46

Size

- 1/4" (DN8) through 6" (DN150)

(Note: 1/4" (DN8) and 3/8" (DN12) sizes uses 1/2" (DN15) body with reducers)

End Connections

- Sizes 1/4" - 2" (DN8 - DN50): threaded, union, flanged

- Sizes 2-1/2" - 6" (DN65 - DN150): integral flanges

Body Material

- Ductile Iron

- Bronze (1/2" (DN15) - 2" (DN50) only)

- Stainless Steel

- Carbon Steel

- Cast Iron (2-1/2" (DN65) - 6" (DN150) only)

Seat Materials

- Jorcote on SST (standard)

Trim Material

- 303SS – standard for Ductile Iron, Bronze or Car-bon Steel valves

- 316SS – standard on Stainless Steel valves

Shutoff

- ANSI Class IV

Float

- Copper — Standard

- Stainless Steel — Optional

Float Arm

- Carbon Steel — Standard

- Stainless Steel or Bronze — Optional

Features and Benefits

- Sliding gate seats provide straight through flow for reduced turbulence and quiet operation

- Compact design and simple construction

- High differential pressure capabilities

- Extremely long packing life with short stroke

- Corrosion resistant configurations with complete 316 SST materials or alloys upon request

Documents