Product description

Reverse Acting: The internal pilot valve seats and the main valve seats are up and closed. As the process temperature rises, the fluid in the sensing bulb vaporizes to apply pressure to the pilot diaphragm thus opening the pilot valve. The upstream pressure passes through the pilot valve, through the pilot port opening the main valve to provide the required cooling action.

As the temperature sensed at the bulb drops, the pilot valve tends to close, shutting off pressure to the main valve's diaphragm. The lower spring closes the main valve as the pressure on the main diaphragm is bled off through the downstream port.

Direct Acting: operated as above except that the pilot valve is normally open and closes on an increase in temperature.

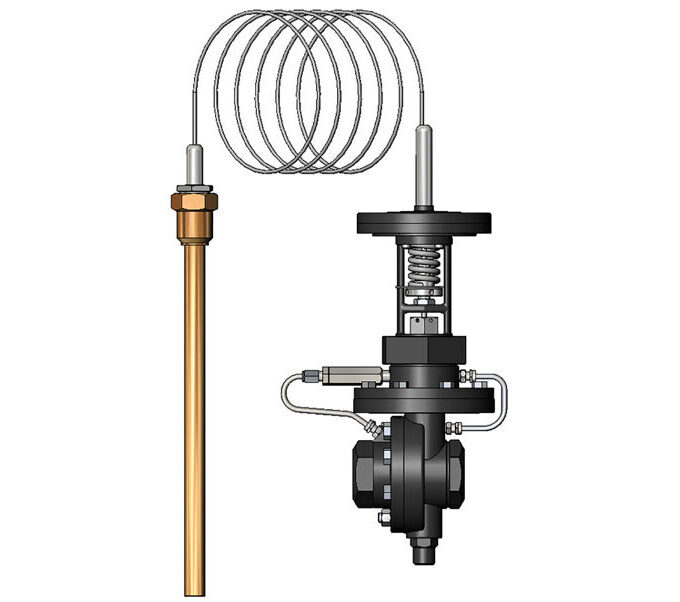

Temperature regulators MK82

- 1/2″ – 2″ (DN15 – DN50)

- Ductile Iron, Bronze

- Threaded, Flanged

- up to 30 (up to 25,8)

- Jorcote on SST

- 10°F (-12°C) to 325°F (163°C)

- All Jordan’s pilot-operated temperature regulators feature the sliding gate technology:

- Short stroke for fast response and accurate regulation

- Easily interchangeable Cv’s

- Extended tight shutoff due to wear resistant coatings and overlap of seat closure area