Product description

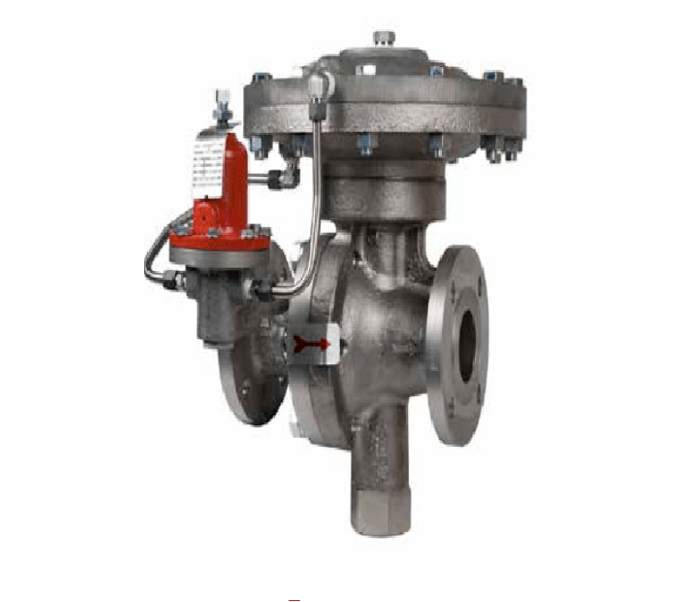

The Mark 67 Series is for critical pressure reducing applications and provides greater accuracy and lower offset than can be achieved with a self-operated regulator. The sliding gate seats provide unsurpassed seat and diaphragm life, easy of installation, simplified maintenance and more accurate performance.Pressure Reducing Valve MK67/69

Size

- 1/2″ – 6″ (DN15 – DN150)

Cv (Kv)

- up to 395 (up to 340)

Diaphragm

- Stainless Steel, Monel, Hastelloy C, Alloy 20

Setpoint

- 10 to 200 psi (0,69 to 13,8 bar)

Body Materials

- Ductile Iron, Carbon Steel, Stainless Steel, Cast Iron

Endconnections

- Threaded, Flanged, Socket Weld, Butt Weld

Features and Benefits

- Mark 67 features the Mark 69 plug-style pilot valves for pressure settings ranging from 10 psi to 200 psi (0,69 bar to 13,8 bar)

- Mark 67 with 69D Pilot offers the optional differential pilot for services where a constant differential must be maintained between two fluids. It is commonly used for atomizing steam and oil for combustion on oil burners where a constant differential between the steam and oil must be maintained.

- An optional air-loaded pilot on the Mark 67 with 69A Pilot allows remote adjustment of pressure set point by changing the air pressure loaded to the dome. The option is recommended where droop must be kept to a minimum, where remote control is needed, or where frequent set point changes may be required

- Main valve features unique Sliding Gate Seats for straight-through flow with reduced turbulence, quiet operation, fast response, and tight shutoff