What are pressure and back pressure regulating valves (PRV & BPRV) and how are they used in the pharmaceutical industry?

A pressure regulating valve is a valve that regulates the pressure of a liquid (liquid or gas), generally by limiting the flow. A back pressure control valve, on the other hand, maintains a constant pressure in a system by preventing the pressure from exceeding a set value. In the pharmaceutical industry, these valves are often used in processes involving the control and distribution of liquids, gases and steam. These valves help to ensure consistent product quality and prevent excess pressure that could damage production facilities or even lead to safety hazards. By maintaining a stable pressure, these valves also help to optimize production processes, increase efficiency and reduce waste.

Is it complicated to select a suitable model and configure a PRV or BPRV?

Choosing the properly model and configuration of a PRV or BPRV is normally the task of the supplier’s or producer’s experts. But even they are experts, they need from your side a minimum amount of information.

We are pleased to provide to you, hereby, an easy step-by-step guide about what information you need to provide for a perfect PRVs and BPRVs model choosing and configuration.

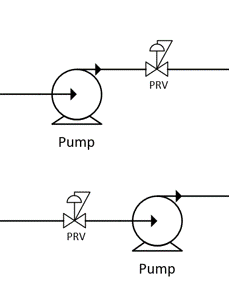

Information needed to choose and configure a PRV and BPRV

Application

A short description of the application/process where the valve will be used is always welcome. It could help the supplier to offer to you the models and options specially designed for it, and to double check the process parameters according to them experience.

The most common pharma applications are for Liquids, Gases and Steam.

Application for Liquids

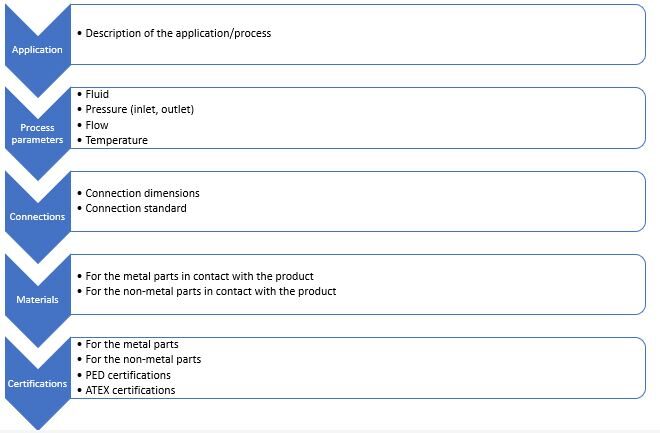

I. Water (PW, WFI) loops

- BPRV mounted at the end of the loop main pipe, to maintain the line minimum pressure.

- PRV mounted in a user point to reduce the pressure according to the maximum pressure supported by the consumer

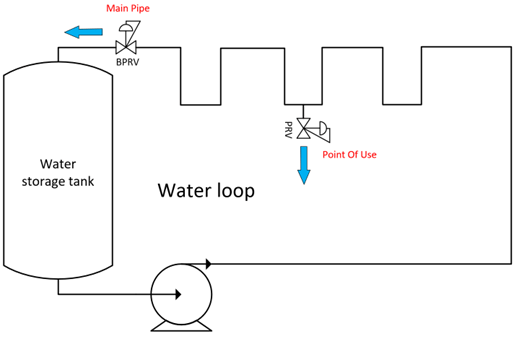

II. Reducing the pressure before or after a

pump

This application is tricky, as the liquids are incompressible, and for some pump types like Positive Displacement Pumps, the pressure will not be well regulated. We strongly recommend to discuss this application also with your pump supplier and to provide to the valve supplier the pump datasheet.

III. BPRV applications that are requiring precise pressure regulation or flow control:

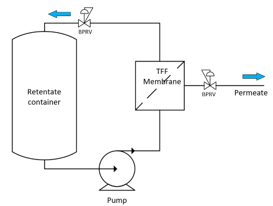

1.Tangential filtration (TFF)

2.Product filling machine

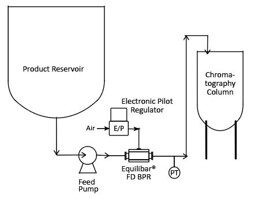

3.Chromatography columns

Application for Gas

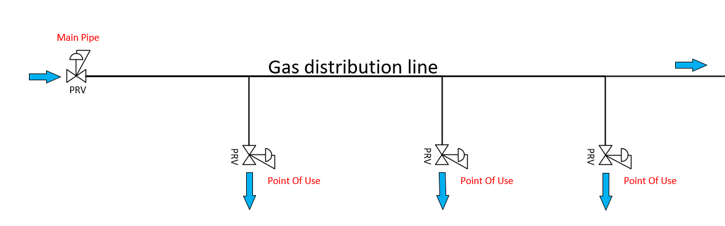

I. Distribution lines

1. PRV used to reduce the pressure for the main distribution line

2. PRV used in a user point to reduce the pressure for the consumer.

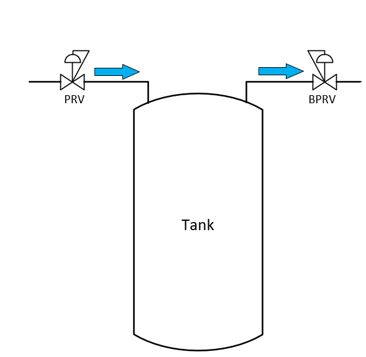

II.Tank inerting, purging or blanketing

1. PRV used to pressurize a tank for inerting, purging or blanketing purposes.

2. BPRV used to protect the tank against

overpressure, during the inerting, purging or blanketing purposes.

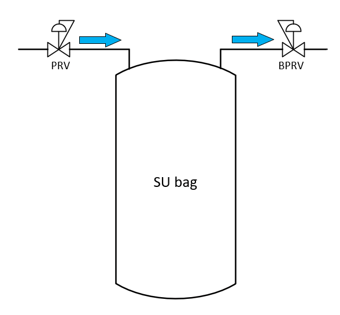

III. Single use (SU) bags inflating

1. PRV used to inflate a SU bag.

2. BPRV used to protect the SU bag against overpressure, during the inflation procedure

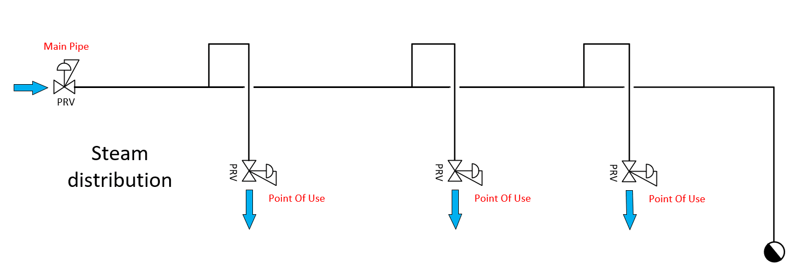

Application for Steam

I. Distribution lines

1. PRV used to reduce the pressure for the main distribution line

2. PRV used in a user point to reduce the pressure for the consumer.

A very important think is to mention if the valve will be sterilized. Is important to know the temperature and the time, because some materials have limited resistance to high temperature exposures.

Process Parameters

The process parameters are the most important ones that gives the valve’s working regime and that are used to choose the valve body with the most appropriate Cvs/Kvs value.

The minimum information to be provided is:

- Fluid

- Inlet pressure (abbreviated P1 or Pin)

- Outlet pressure (abbreviated P2 or Pout)

- Flow

- Process temperature

Very Important tips related to the measurement units:

- Avoid to use simple bar unit, especially for the gases (including steam). Be more specific and use bara (if the pressure is absolute) or barg (if the pressure is relative to the atmospheric pressure). The difference is very important as P[bara]=P[barg]+1 and has a big impact in the gas applications. If you are not sure if is bara or barg, please note that the majority of the field instruments are giving the barg value, indicating 0 at atmospheric pressure (when the system is not pressurized).

- For the gases (not valid for steam) is very important to give the flow in normal conditions (t=0oC, P=1,01325 bara), so the measurement unit should be Nm3/h or NL/min (NLPM). Do not give m3/h or L/min (LPM), because the gases are changing them volume according to the pressure and temperature.

- For steam, the most common measurement unit for flow is kg/h, and is a mass flow, not a volumetric one. This is because the steam is condensing into water, facing a huge volume change, while the mass is remaining constant.

- For the steam is very important to take care that the steam consumption during the sterilization start-up could be 10 times bigger than the consumption during the heat-up of the system, and 100 times bigger than during the sterilization itself. The best approach when choosing the right PRV is to consider the consumption during the heat-up and sterilization, not the maximum one reached in the start-up phase (when the system could be vacuumed). If you have doubts about the consumption, is better to ask an expert evaluation.

Connections

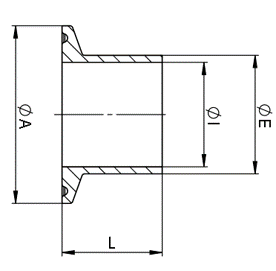

For both, inlet and outlet, you should specify the:

- Connection standard (e.g. ASME BPE, DIN, ISO)

- Dimensions (e.g. ½”, ¾”, 1”, etc. for ASME BPE, or DN15, DN20, DN25, etc. for DIN and ISO)

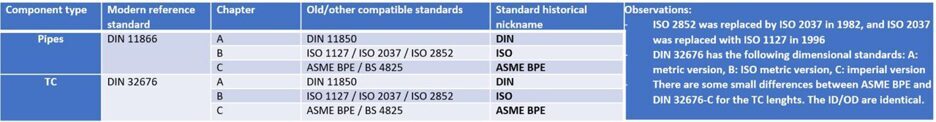

Regarding the connection standard, the most common are the so called ASME BPE, DIN and ISO. Actually, these are historically inherited names, which are somehow obsolete, but still used even the standards evolved, and nowadays have more sophisticated names.

We tried to summarize below these common standards as are used in Europe:

Another standard used by some companies is DIN 11864 which have 3 types of connections, each one having ASME BPE, DIN and ISO pipe dimensions.

Materials

The following material\'s informations will be useful to choose and configure a PRV and BPRV

I. The body material

Water (PW, WFI) loops

- Stainless steel: 316L -1.4435 -BN2 1.4435

- Other special materials

II. The body material surface finish (roughness)

It is mandatory to specify the roughness for the metal parts that are in contact with the product (wetted parts). Optional you can specify it for other parts. The roughness should be chosen according to the pharma organizations recommendations or to your company quality policy. Some examples of roughness are:

- 0.8 µm (equivalent with 32 µin or 32Ra): it is an acceptable roughness for the water loops

- 0.5 µm (equivalent with 20 µin or 20Ra): it is an acceptable roughness for different systems like preparation/filtration skids.

- 0.2 µm (equivalent with 8 µin or 8Ra): it is a top roughness for high class systems like filling machines.

III. Diaphragm material

It is only for the valve’s robustness. The best choice is the Jorlon material.

Other possible options could be EPDM and stainless steel.

Here you have 2 criteria: the process temperature and the seal requirement. If is a steam application, you should choose the PEEK material. Otherwise Jorlon, Teflon or stainless steel. If you do not want to have leakages when the valve is fully closed (you need fully sealed), do not choose the stainless steel.

Certifications

There are available a lot of certificates. The most common requested are:

- EN 10204 3.1 for the metal parts in contact with the product

- FDA / USP CLASS VI for the different plastic parts in contact with the product

- PED (Pressure European Directive) compliance

- ATEX certification (for applications with explosion risk)