Our PBM (TRUE BORE) 2-way ball valves are suitable for pure process and pure steam applications. Forged and cast ball valves contain a low ferrite content. Our unique Adjust-O-Seal® feature allows in-line valve adjustment to compensate for normal wear of the valve seats.

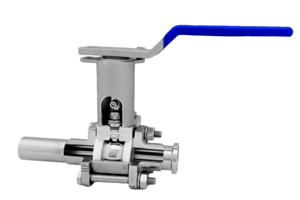

2-Way Sanitary Ball Valve

Size

- 1/4″ - 6″ (DN06 - DN150)

Material

316L low ferrite cast and forged

Hastelloy™, AL6XN™, others uppon request

seats and seals standard: V-TEF™

End Connections

Standard: extended Welding ends, Triclamp

other connections available on request

other connections available on request

Working pressure

Up to 62.1 bar (900 psig) depending on valve series, size and temperatures

Temperature range

up to 232.2˚C (450˚F) depending on seat and seal material

CV values

- 6.5 to 5,000 depending on end connection

Features and Benefits

- Constant continuous diameter (True-Bore®) whether ISO, DIN or US

- The valves are designed for full vacuum.

- Various surface finishes available incl. electropolishing

- Certified Material Test Reports (CMTRS) for wetted components

- ASME BPE compliant

Options

- Full Range of Automation and Controls

- Optional body cavity fillers minimize areas where media could become trapped and contaminate the process

- Optional Patented Locking Lever Handle

- Optional Self-flushing ball completely cleans valve internals during line flush Piggable

- Optional Clean Steam and Trap Design, purges or drain ports